The past two weeks have been kinda crazy with work, home, preparing my kids for the school year, etc. I found some time to continue prepping R2 for a first run with R/C. Before I could do anything, I needed to strengthen some areas and reduce the side to side wobbling. This wasn't coming as much from the shoulders as it was the ankles. I did need to fill the shoulders out, which also adds stability to that area. After several failed attempts at cutting these circles out of wood with a Rotozip, I decided to go back to the old jigsaw method, and had these cut out in no time. These parts sit snugly inside the shoulder between the shoulder hubs and the outer PVC shoulder. I haven't fastened these to the leg permanently as I'm still unsure if I will keep these legs for this droid or replace them with A&A legs and save them for droid number 2. Either way, they give strength to that area and I'm happy with the results.

I cut and laminated the ankle locks. These parts restrict the movement of the foot at the ankle and keep the foot relatively level. They also prevent the foot from turning inward, under the body. I also found that I needed to add a piece of .040" styrene on the inside ankle where it attached to the foot. This also prevented unnecessary side to side movement in this area. You can see where my first cable pass through hole was placed. Looking at the plans for the ankle, there was a hole drilled there and I didn't find any real explanation for it. Unable to bend the cable through there, I consulted my fellow builders (thank you Calvin!!) and re-drilled the hold at the bottom. This connection is temporary, as I will need to re-route the cable in the foot to better conceal it before covering the foot with the foot shells - but for now, it will do.

I had these parts leftover for years. These are rubber bumpers that I got somewhere... but I find uses for them. In this case, this will provide stability, and little cushion for my electronics panel. These bumpers will keep the panel from sliding in or out of the frame.

I needed a solution to hold the electronics panel in place on the frame, but make it removable as I will need to access the battery compartment behind it. I used scrap pieces from when I purchased the frame (this is a kidney shaped piece that is 1/2" thick, originally a cutout from the shoulder hubs...). After drilling a hole large enough to fit and end of a T-nut, I JB Welded the T-nut and glued the whole thing to the frame. Rubber washers will help reduce some of the shock where the bolt passes through the panel.

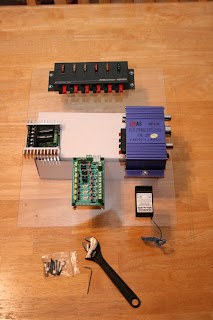

Electronics panel installed. This is set up only for the foot drives. I have an in line fuse placed on the 24V power cable (30amp fuses). Probably won't do much as I only expect to max out at 14-15amps at start up, but it's there none the less. Since I don't have a 12V battery yet (still on my "to order" list....), the Rigrunner fuse box at the bottom is left disconnected. I routed the cabling from my radio receiver to run 5v power from the foot motor controller. This is just for testing purposes as once I receive a 12V battery, power for the receiver will be drawn from the 12V power distribution (green board at the top/center of the panel...).

I just put batteries in my transmitter and programmed channels 1 and 2 as "mixed" signalling. Just need to find time to test the systems.